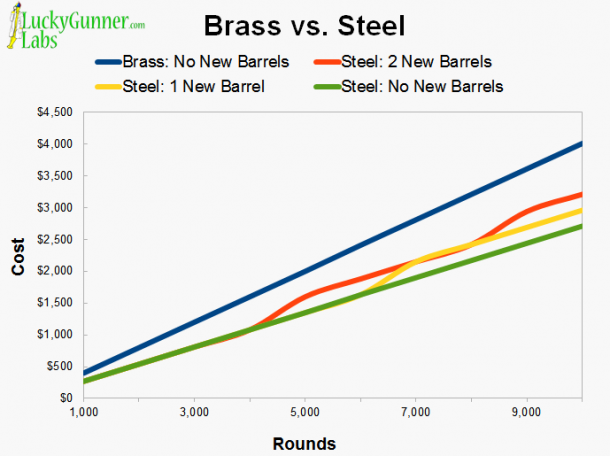

Unfortunately, its not just all about the cost. Some shooters care about other parameters, such as reliability and accuracy.cyphertext wrote:Whatever...Bitter Clinger wrote:I don't need YouTube, I prefer real life experience. But thanks anyway, if it makes you feel better then I'm satisfied.cyphertext wrote:The barrel on an AR is consumable and easily replaced. When you can shoot steel cased ammo and have money from the savings to replace the barrel and still be ahead... well, I don't see that as a problem.Bitter Clinger wrote:Go ahead and strip your rifling out prematurely, not my problem.cyphertext wrote:I saw that report from Lucky Gunner... but I don't shoot at the same rate that they do... and have seen other reports that suggest a different theory on the barrel wear, that it is actually the propellant and not the bi-metal jacket that wears the barrel. But in either case, one can shoot that stuff and replace a barrel with the savings over brass and still come out ahead.Bitter Clinger wrote:We have also found that the Russian steel cased ammo does not use the more costly copper jacketed lead bullets. The bullets appear to be copper plated only and the bullet itself appears to have iron mixed in - if you check you will find that the bullets are magnetic. The use of these rounds will lead to early barrel replacement.cyphertext wrote:I'm going to respectfully disagree... while this was true in the past, steel cased ammo today is no longer covered in lacquer. Also, back when folks would get steel cases stuck in the chamber, most were shooting 20" rifles. With a carbine length gas system, and the higher pressures involved, reliable extraction can be achieved using steel cased ammo. Add in the O-ring enhanced extractor and I doubt you will have any issues.The Annoyed Man wrote:I would amend the above to make sure to only buy brass-cased ammo. I know that plenty of people shoot the steel-cased varnished stuff, but the .223/5.56 case doesn't have enough taper to use that kind of ammo reliably. I've seen WAY too many fired steel cases stuck in AR barrels that wouldn't extract for love or money......some times so badly that running a rod down the barrel and trying to tap the case out won't remove it. Then you need a gunsmith with a chamber reamer. Brass cases OTH have natural lubricity and are very good at extracting cleanly.

Steel cased ammo is fine for AK pattern rifles because the case has a pronounced taper and extracts easily.

And remember, not all steel cased ammo is created equally... there is a big difference between Tula and Hornady Steel Match, and a price difference that matches as well.

Maybe this will help...

https://www.youtube.com/watch?v=P5ZB3UfG960

Keep running steel as long as you know how to find cover. Here are the reliability results (excerpts) from that same study:

Federal: 10,000 rounds, 0 malfunctions.

Brown Bear: 10,000 rounds, 9 malfunctions (5 stuck cases, 1 magazine-related failure to feed, 3 failures to fully cycle)

Wolf: 10,000 rounds, 15 malfunctions (stuck cases)

Tula: DNF (6,000 rounds in alternate carbine, 3 malfunctions)

The carbine firing Tula had a case stuck in the chamber after 189 rounds which proved exceptionally difficult to clear, even with the use of a steel cleaning rod after the rifle had cooled. Over the next three hundred rounds, 24 malfunctions – stuck cases and failures to fully cycle, or “short stroking” – were encountered. At this time, the Tula carbine was removed from the testing, as the problems were causing significant delays.

A decision was made to fire the remainder of the Tula ammunition through other carbines. Approximately 300 rounds were fired through an HK416 (no malfunctions), 1,000 through a Spike’s Tactical carbine (3 malfunctions), and 6,000 through a Spike’s Tactical midlength without any cleaning (3 malfunctions). All malfunctions with the other carbines were stuck cases or failures to eject.

...A decision was made to fire the remainder of the Tula ammunition through other carbines. Approximately 300 rounds were fired through an HK416 (no malfunctions), 1,000 through a Spike’s Tactical carbine (3 malfunctions), and 6,000 through a Spike’s Tactical midlength without any cleaning (3 malfunctions). All malfunctions with the other carbines were stuck cases or failures to eject.

At the 5,000 round mark, the bolt carriers, upper receivers, and barrels were cleaned. After observation of high speed video showed inconsistent cycling, action springs ($3) were replaced, as were extractor springs ($6.99) and gas rings ($2.19).

The second half of the test started off with several malfunctions with the Brown Bear carbine – at 5,200 and 5,250 rounds, short stroking malfunctions were encountered. High speed video showed that the bolt was barely coming back far enough to pick up the next round, and occasionally not even far enough to eject the spent case. Additional lubrication did not prevent the second malfunction.

A detailed physical examination revealed previously unnoticed carbon buildup in the gas key and gas tube which had almost completely occluded those components. The other firearms were inspected, and none exhibited carbon buildup which was even remotely close to that of the Brown Bear carbine. Cleaning of these components in the field proved difficult to impossible, and it was decided to set them aside in order to examine the phenomenon.

The gas tube and bolt carrier of the Brown Bear rifle were replaced with identical components, after which firing resumed without incident. No malfunctions occurred until 7,500 rounds, when five stuck cases were encountered between 7,500 and 8,200 rounds. From 7,500 rounds on, a number of cases with distended and/or split necks were observed.

But in this test, we saw three times as many failures to extract with the polymer coated Wolf brand ammo (15 extraction failures) than with the lacquer coated Brown Bear ammo (5 extraction failures). Although the polymer coated Tula ammunition was fired in different rifles, the rate of extraction failures in those rifles was lower than that of Wolf.

And what about accuracy? Or doesn't that matter?

I would expect that a carbine shooting brass cased, copper jacketed lead to last at least ~20,000 rounds before needing re-barreling.While the carbine firing Federal ammunition maintained acceptable accuracy up to and including the 10,000 round mark, the Brown Bear and Wolf carbines exhibited significant accuracy loss by the 6,000 round mark. It is quite possible that this first started occurring earlier than 6,000 rounds, because groups at 4,000 were well within standards of 5MOA or less, while some shots at 6,000 “keyholed,” or impacted the target sideways.

As indicated by accuracy testing, the steel cased/bimetal jacketed ammunition caused accelerated wear to the inside of their respective bores. While the barrel of the Federal carbine had plenty of life left, even after 10,000 rounds at extremely high rates of fire, the Wolf and Brown Bear barrels were subjected to the same rates of fire and were completely “shot out” by 6,000 rounds.

At the end of the test, the chrome lining of the Wolf and Brown Bear barrels was almost gone from the throat forward, and the barrels had effectively become smoothbores, with the rifling near the muzzles acting only as a mild suggestion on the projectiles. A throat erosion gauge could be dropped into the bore from the muzzle end with absolutely no resistance.

Anyway, like I said, not my problem.